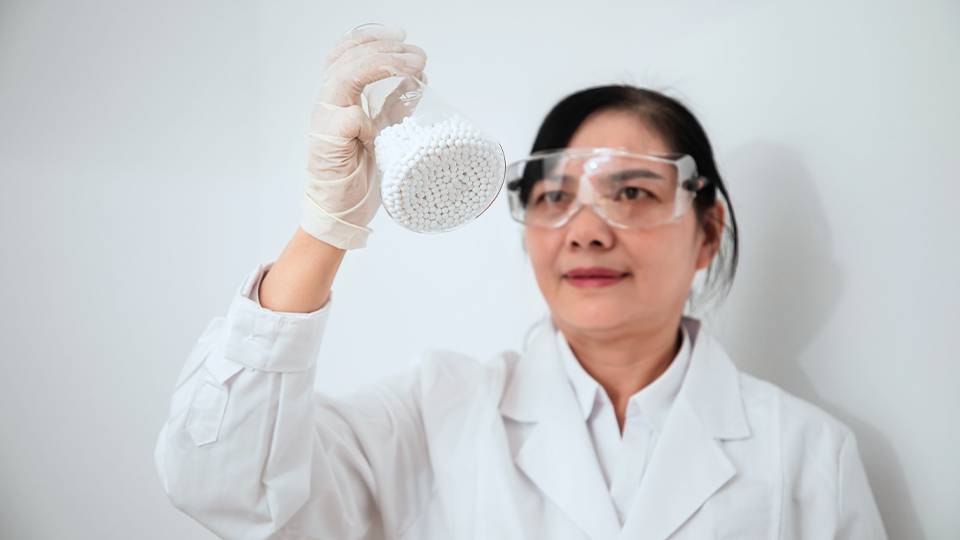

Manufacturer of Activated Alumina

Chempack is the approved OEM catalyst and adsorbent supplier of Sinopec and PetroChina. We are your reliable manufacturing partner to actualize your product and process ideas from concept to commercialization. And our integrated technical solutions will help you succeed in running a more productive, cost-efficient, eco-friendly production on stream.