Specialty adsorbents work on the purification of raw materials by attracting impurities to itself, treating the material from unwanted factors that can affect the production and product quality. Raw material passes through the sphere or granule-shaped adsorbents to initiate the filtering process. Impurities like polar compounds, sulfur, and mercury will cling to the surface of these adsorbents that create a film around them. The adsorbents are then taken out of the machine through disposal channels, while the purified material continues the later treatment process.

Petrochemical facilities and chemical treatment facilities would benefit best from having effective specialty adsorbents included in their treatment and filtration systems. While general-purpose adsorbents can filter out some impurities on materials, having an adsorbent that specializes on a specific chemical is a more effective and cost-friendly option. Residual impurities can lead to damage to the equipment that could cost a lot in repairs or replacements while creating a low-quality final product that either sells low or would not sell at all.

Chempack sees the demands for high-quality specialty adsorbents that are also low-priced. The company is teamed up with research facilities that specialized in advanced adsorbents to develop a product line that meets not only industry standards but also a cost-effective goal. Activated alumina and carbon, as well as a proprietary compound, are used as main components of these adsorbents for contaminant removal. Activated carbon handles the removal of carbon, sulfur, mercury, and odors, as well as solvent recovery. Activated alumina, combined with hydrogen peroxide, is used for specific purification and chemical removal.

Chempack is dedicated to providing specialized solutions to petrochemical plants and chemical treatment facilities. As such, we developed specialty adsorbents using a combination of pure synthetic polymers, advanced engineering, and constant improvements. We consistently partner with industry leaders and experts to assure that our line of adsorbents gets their job well done.

With the goal of providing specialty adsorbents, we also work with our customers to customize adsorbents based on their needs. Calculations are also provided to show customers the predicted effectiveness of the products before order completion. Adsorbents have high pore volume and uniformly made, ensuring each piece can attract the same amount of impurities, while keeping its form.

As customers may have different needs depending on their industry or products, our adsorbents offer flexibility and customization options to address the perceived needs. Our team of research and development specialists can make necessary adjustments to our product orders to match specifications the customers provide. Calculations are also done and presented to customers to show expected results before order placed, providing the assurance that the adsorbents meet or even exceed expectations.

Our lines of specialty adsorbents are made to be very porous to draw out as many impurities from the raw material as possible at a consistent rate. Products use varieties of pore types to maximize adsorption and material retention. This gives an assurance that unwanted acid gases, water, polar compounds, and other impurities are completely removed from the system.

The mechanical process utilized for manufacturing the adsorbents gives each one a durable, uniform appearance. This uniformity gives the assurance that each piece will work exactly the same, maximizing its functionality. The process also makes the adsorbents resistant to wearing, which can have adverse effects on the filtering process and the final products.

Refining adsorbents to remove water, sulfur, and other contaminants from hydrocarbon streams.

Petrochemical adsorbents to remove water, sulfur, and other contaminants from feed to product streams.

Porous natural gas adsorbents to remove trace contaminants for efficient and effective gas processing.

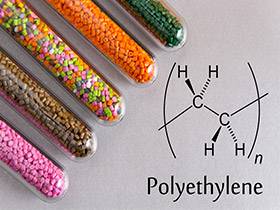

Polypropylene adsorbent to remove COS, water, and other contaminants from polypropylene production.